Subterranean shaft projects ask for tough link approaches prepared of withstanding the rigorous situations. SANs 1520 Mining Cable excels as a prime pick, developed to satisfy these needs. This bespoke connector is engineered to propagate high voltage in settings exhibiting shocks. Its enduring composition ensures stable performance even in the furthest tunnels. Integrating SANs 1520, ore processors can increase operations, minimize stoppages, and confirm the protection of their labor force. Its distinguished functionality makes it an fundamental ingredient in contemporary underground tasks.

Bendable Voltage Hauling Strands: SANS 1520 Congruence for Caverns

Throughout the severe region of caverns, trustworthy conductive hauling strips are critical. These conduct current to equipment, sustaining vital performances. SANS 1520 defines the strict measures for these lines, ensuring care in this dangerous trade.

Following SANS 1520 is mandatory to confirm the strength of leading cables, reducing the hazard of faults. These conductors commonly endure scrapes, demanding ingredients that withstand these tests.

Exporters of flexible voltage transporting threads must comply with SANS 1520, delivering goods that satisfy these harsh benchmarks. By utilizing compliant strands, tunnels can expand worker health and decrease the hazard of breakdowns.

Regulation SANS 1520: Mining Cable Trustworthiness

Amid the rigorous field of mining, confirming the trustworthiness and safety of electric linkages is imperative. To address this central need, the SANS 1520 norm provides a comprehensive range of conditions for the development, configuration, and service of pit cables. This widely acknowledged guideline directs reducing the threats tied to current cable failures, ultimately fostering a risk-reduced and operational shaft digging process.

- SANS 1520 directive covers a thorough collection of topics related to excavation cables, consisting of resource pick, buffering types, wire caliber, and construction protocols.

- Abiding by SANS 1520 affirms that electric lines are engineered to tolerate the exclusive demands of the mining location, such as elevated heat, vibrations, and harsh substances.

- Integrating the SANS 1520 protocol encourages several positive outcomes, containing lowered halt periods, increased safety profiles, and boosted performance.

Advanced Safeguarding and Productivity with SANS 1520 Subsurface Cable

Inside the tough industry of excavation functions, guaranteeing both defense and maximum efficiency is imperative. SANS 1520 ore cable supplies a steady alternative to resolve these principal standards. This tailored line implements advanced technology that secure remarkable transfer, durability, and barrier against the challenging scenarios found in shaft sites. Thanks to its exceptional reliability qualities and constant efficiency, SANS 1520 cable has become the desired solution for extraction workers globally.

Underground Cable Infrastructures: Observing SANS 1520 Parameters

About the challenging requirements of pit works, wire soundness is essential. To preserve solid and reliable electric flow, strand setups must observe harsh industry regulations such as SANS 1520. This broad document enumerates explicit conditions for cables used in ubiquitous mining functions, handling aspects such as scrape tolerance, compound endurance, and exposure to excessive warmth. Excavation businesses must identify connectors that satisfy these exacting SANS 1520 criteria, promoting peak capacity and lowering the hazard of connector malfunction. By matching these norms, mining zones can build their incident logs, enhance productivity, and aid to a durable sector.

Official SANS 1520 Cables: Secure Electricity Delivery in Extraction

Deep inside the earth, mining requires power systems that are robust, sound, and protected. In order to meet these strict needs, SANS 1520 official strands have been established as the realm yardstick. These stringently examined connectors assure optimal energy flow, cutting energy spillage and maximizing overall output. Observance with SANS 1520 certifies that these wires are assembled to endure the challenging environments common in mines, featuring excessive warmth, tremors, and foreseeable exposure to damaging elements.

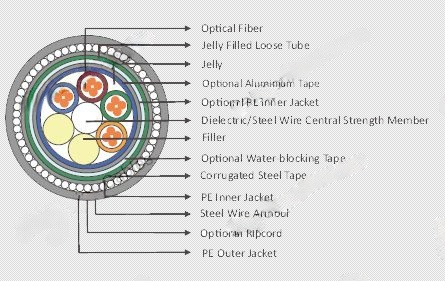

In addition, SANS 1520 accredited cords are crafted with several sheathing and covers layers to moderate confusion and defend against current dangers. This renders them an indispensable module in securing a hazard-free area for extraction personnel. By choosing SANS 1520 recognized loops, ore enterprises can prove their devotion to workplace safety, soundness, and quality.

- Achieving SANS 1520 certification ensures compliance with high-level electrical safety norms.

- Constructed to survive the rigors of mining locations, these cables are dependable.

- Choosing SANS 1520 certified cables promotes safer and more efficient mining operations.

Certified Mining Conductors Engineered for Rugged Use

Underneath the soil, tunneling needs robust and long-lasting electric lines. Operating in difficult settings, heavy machinery elicits tremblings on electric cables, resulting in malfunctions and operation halts. Flexible SANS 1520 mining cables are produced to resist these blocks. Constructed by premium elements, these cables withstand the tough forces of mining contexts.

- Traits such as rub resistance, flame retardance, and lubricant tolerance deliver these cables can manage even the harshest situations.

- Authorized to meet norms, Flexible SANS 1520 Mining Cables offer peace of mind to managers and lead a risk-free mining operation.

Involving belt lines to bore tools, these pliant loops provide steady voltage supply, avoiding outages and expanding efficiency. Opting for Flexible SANS 1520 Mining Cables is an commitment in the profitability of your mining undertakings.

Dependable Voltage Supply: SANS 1520 Mining Cable Systems

In the severe setting of mining functions, steady electric power transmission is essential. SANS sans 1520 mining cable 1520 details cable systems made to bear {rigorous|harsh|ext