{Catering to stringent requirements regarding cryogenic functions necessitates professional valve technology. Our subzero 3-way globular device alternatives are crafted to provide dependable output even at polar temperatures, typically below -150°C. These devices offer remarkable circulation optimization in liquefied materials such as nitrogen, oxygen, and argon, frequently deployed in realms like LNG, research equipment, and clinical facilities. The organization value sturdy construction, including low-resistance sealing materials and careful machining, to validate closed functionality. Review the gains of boosting your subzero system with our innovative 3-way spherical valve systems.

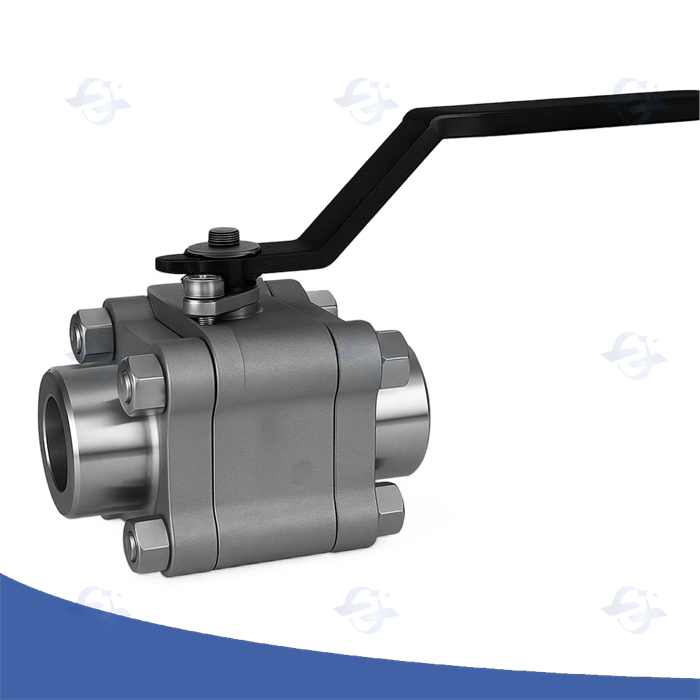

Top-Quality Double Block and Bleed Ball Valve Assemblies

As for crucial systems, particularly where leakage is restricted, top-tier double block and bleed valve systems offer distinctive protection. This unique design incorporates two individual seal valve seals, further a bleed hole, allowing for verification of the entire shut-off and detection of any conceivable oozing. Commonly employed in fuel extraction, processing transformation, and chill surroundings, these units considerably boost facility dependability and mitigate the chance of environmental footprint.

Triangular Flow Frosty Round Component Architecture

A design of three-port cryogenic circular instrument presents a particular engineering complication. These assemblies are generally employed in critical industrial tasks where stringent coldness must be secured. Key factors include ingredient election, expressly regarding fragility at minor temperatures, and the necessity for sealed shutting to ward off leakage of glacial substances. Elaborate analysis styles and thorough construction routines are vital to assure steady efficiency and endurance under such challenging functional situations.

Cryogenic Monitor Performance in Technical Applications

An demanding criteria of cold processes, such as cryogenic natural gas handling and chilled nitrogen storage, necessitate trustworthy instrument systems. Integral block drain assemblies provide a particularly robust and effective solution to achieving zero-leak seal while facilitating periodic maintenance. Their design embeds a primary mechanism with a small vent corridor, allowing monitored pressure discharge during cutoff and reactivation. This inherent characteristic minimizes leftover item entrapment, thereby ensuring paramount safety and performance even under the most harsh engaging cases. Furthermore, the skill to monitor bleed discharge provides valuable assessment insights for plant refinement.

Securing 3-Way Orbital Valve Locking in Critical High-Pressure Applications

Securing secure closure performance with 3-way ball valves becomes particularly essential when operating within considerable pressure scenarios. The design should account for significant loads and potential discharge pathways. Specialized components, often including state-of-the-art metals like corrosion-resistant steel or exotic alloys, are imperative to resist the tough conditions. Furthermore, advanced mounting geometries and fine development processes are vital to minimize flow and guarantee a leak-proof bond even under fluctuating torque cycles. Regular inspection and planned overhaul programs are also vital for endurance and unbroken operational integrity.

Subzero Ball Valve Leakage Prevention Strategies

Curtailing "oozing" from cryogenic "ball valves" demands a multifaceted "strategy". Initial "blueprint" considerations are paramount; material "decision" must account for extreme "chills" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "constituent", meticulous "fabrication" processes – including stringent weld "inspections" and non-destructive "evaluation" – are vital to ensure structural integrity and eliminate voids that could become "escape routes". A "essential" component is proper "placement"; thermal "shrinkage" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "preservation" – including periodic "review" for signs of wear and "repair" of any identified issues – is indispensable for maintaining a reliable, leak-tight "closure”. Ultimately, a robust "strategy" incorporating these elements is necessary to ensure the safe and efficient "activity" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "shrinking", safety "dangers", and costly "breakdown”.

Parallel Shutoff and Discharge Instrument Review Methods

For certifying the integrity and safety of critical piping lines, rigorous double-layer barrier and discharge instrument testing protocols are essential. These tests, often mandated by regulatory bodies and industry best practices, typically involve simulating simultaneous closure of two isolation units while simultaneously ensuring the discharge instrument remains functional and correctly discharges any trapped commodity. A common method is to utilize a pressure examination where the system is pressurized to its maximum working pressure, and the leakage rate around the closed instruments is meticulously recorded. The escape mechanism's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of assessment results, including any exceptions observed, is necessary for maintaining a reliable activity.

Realizing Thorough Block Emission Unit Functionality

In order to properly handle pressure systems, a meticulous awareness of integral block bleed apparatus performance is undeniably indispensable. These specialized devices mostly work to reliably eject superfluous compression from a network during defined functional steps. A conventional arrangement consists of a fitted volume attached to the key tension source, granting certain led expulsion as soon as essential. The built-in construction minimizes the possibility of pressure overload, guarding both the installations and the encompassing setting. Regular assessment and upkeep are crucial to safeguard premium effectiveness.

Determining the Proper 3-Way Ball Valve for Cryogenic Fluids

Electing a adequate 3-way-ball component for cryogenic deployments demands careful evaluation of several critical elements. The extremely low thermal drops inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present distinctive challenges. Material decision is paramount; only materials with proven fitting and ductility at these temperatures, such as alloyed steel grades like 304L or 316L, or specialized alloyed alloys, should be scrutinized. Furthermore, the device's sealing efficiency is vital to prevent discharges, requiring specialized stem sealing structures and low-temperature fluids. Finally, pressure scales and actuation means, taking into account potential pressure variations, must be thoroughly matched to the system's demands. Neglecting these factors can lead to disastrous failure and safety perils.

Glacial Circular Valve Component Harmony Catalog

Electing the appropriate component for cryogenic rotary valves is paramount, given the rigorous temperatures involved. This handbook highlights common components and their functionality when exposed to cryogenic fluids such as fluid nitrogen, solution helium, and oxygen. Stainless steels, particularly sorts 304 and 316, often demonstrate adequate resilience and rust resistance, though martensitic alloys require careful consideration regarding embrittlement. Aluminum alloys can be suitable for certain applications, however, their workability and endurance to specific chemicals needs detailed evaluation. Copper alloys, while offering some plus points, may exhibit subdued functionality at these diminished temperatures. Consultation with fabricators and comprehensive evaluation is essential to assure endurance and safety in cryogenic operations.

Enhancing Double Seal and Release Installation Performance

Securing optimal output in double shutoff and vent constructions hinges on a multifaceted methodology. Careful scrutiny of component selection is vital, with a focus on compound compatibility and force assessment. Regular assessment of bleed channels for congestion is mandatory, often obliging the use of specialized testing equipment. Furthermore, methodology improvement—including inspection of transit rates and tension contrast—can dramatically advance overall installation firmness and guarding. Finally, congruence to fabricator directives and the enforcement of a complete maintenance routine are critical for long-term sustainability and lastingness.

Cryogenic Ball Valve

Cryogenic Ball Valve